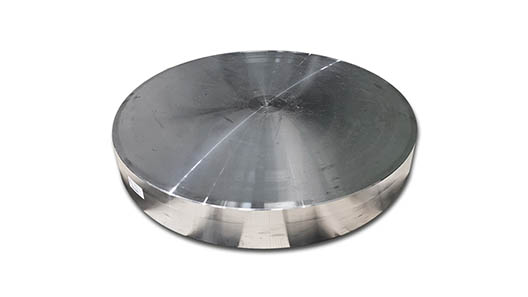

Stainless Steel 304 Forged Blocks

Stainless Steel 304 is a versatile alloy made primarily from iron, chromium, and nickel, with a specific blend of carbon content, making it highly resistant to corrosion, oxidation, and staining. Forging this material involves heating it to high temperatures and applying controlled pressure to mold it into desired shapes. The result is a forged block that is dense, strong, and highly resistant to wear and tear, making it ideal for applications that require both toughness and precision. One of the primary benefits of 304 stainless steel is its outstanding resistance to a wide range of corrosive elements, including acids, saltwater, and chemicals. This makes 304 forged blocks ideal for use in environments exposed to harsh conditions, such as marine, food processing, and chemical industries.

Ferrobend ensures that each 304 forged block is produced with the utmost care, resulting in a product that exhibits exceptional tensile strength and impact resistance. Whether used in heavy machinery, valves, or structural components, these blocks are designed to withstand high-stress environments without compromising on performance.

Stainless Steel 304 is relatively easy to machine, allowing for precise and custom designs to meet specific project needs. Ferrobend offers bespoke fabrication services, ensuring that 304 forged blocks are cut, shaped, and finished to meet any unique specifications required by clients.

304 stainless steel has excellent heat resistance properties, with the ability to withstand temperatures up to 870°C (1600°F) in intermittent service. This makes it highly effective for use in high-temperature environments, such as in automotive exhaust systems and high-heat industrial processes.